06-January-25

Watlow has a large portfolio of products, sold across multiple industries, and used in a wide variety of applications, with deep expertise on applications related to thermal systems and their control.

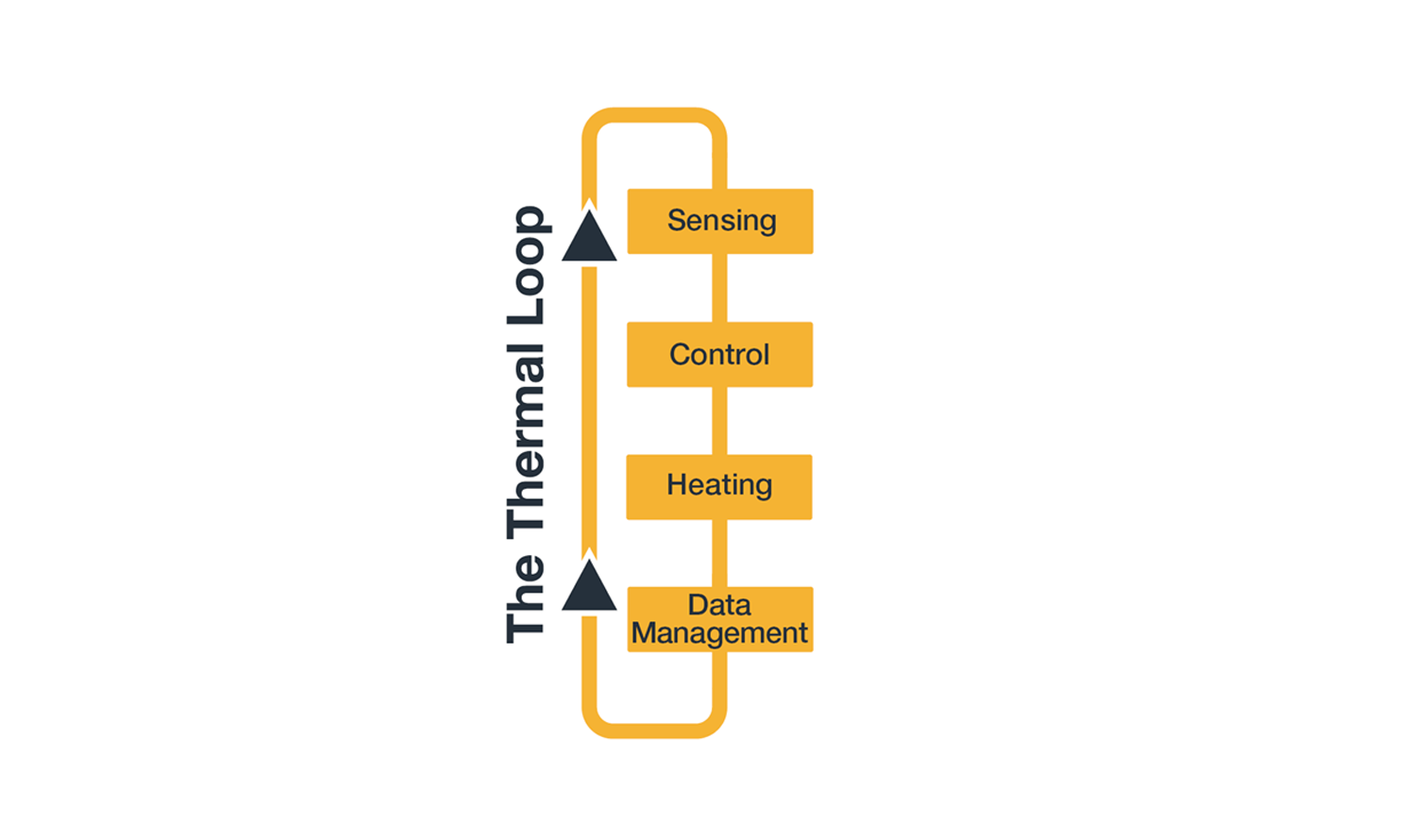

For Watlow, the underlying concept behind everything they do is that of the thermal loop. Every product offered, and every project worked on, is ultimately about the creation and control of a thermal loop in some application. There are four foundational components or elements of the thermal loop; sensing, control, heating and managing the integrity of the data, which helps optimize that process.

Eurotherm have a solid reputation for their deep domain knowledge and expert solutions in managing data integrity, particularly in highly regulated industries such as life sciences, heat treatment, and food and beverage manufacturing; solutions designed for dairy plant milk pasteurization and a pyrometry solution for the aerospace industry illustrate this well.

A thermal loop is a kind of system designed to precisely control the temperature of a part, fluid, or environment. Precise control of temperature requires more than simply heating—it also requires accommodating for variation in the system such as fluctuations in voltage or environmental conditions and adjusting accordingly to maintain consistent system performance. In some cases, a single component can play multiple roles. For example, with high temperature coefficient of resistance (TCR) materials, it is possible for a single component to act as both a heater and a sensor, which cuts down on the total number of components and wires needed in the system.

Another critical choice in the design of any industrial thermal system, is the selection of a power controller. Dependent on a host of factors that go well beyond simple power requirements. The Watlow family of power controllers is significantly extended when combined with the Eurotherm line offering a comprehensive spectrum of functionality. This wide variety of features and performance means customers can choose the level of sophistication they require to efficiently manage processes and reduce energy costs—without paying for more functionality than is necessary.

Advanced options for greater efficiency

The data management component of thermal loop for highly regulated industries

Rapid world growth, globalization, advanced technologies for Industry 4.0 automation and data analysis trends, are emphasizing the need for high standards of data quality and integrity across multiple industries but this has always been the case where safety and traceability are critical factors. Good data practices (GxP) enrich the quality of data, enabling companies within highly

regulated industries to make strategic decisions based on trustable data and analytical insights. In these industries, it is not enough to provide precise temperature control, there also needs to be an end-to-end data record. This record provides evidence of compliance of the procedure and that the required results were achieved for every batch, at every stage of the process.

Eurotherm have specialized knowledge and experience in these industries, delivering solutions that help businesses to reduce the time and cost of regulatory compliance, throughout their manufacturing processes and supply chains. Eurotherm solutions and services help customers to efficiently manage the quality, safety, and the authenticity of manufactured goods in multiple ways. Through machine and process automation efficiency, high integrity data management and by partnering with global regulatory bodies to help improve on best practice engineering approaches, such as the ISPE on GAMP® 5 (Good Automated Manufacturing Practice).

© 2024 Eurotech Controls & Instruments Pvt Ltd. All Right Reserved.

Designed & Developed by  Innov Touch Technologies Pvt Ltd.

Innov Touch Technologies Pvt Ltd.